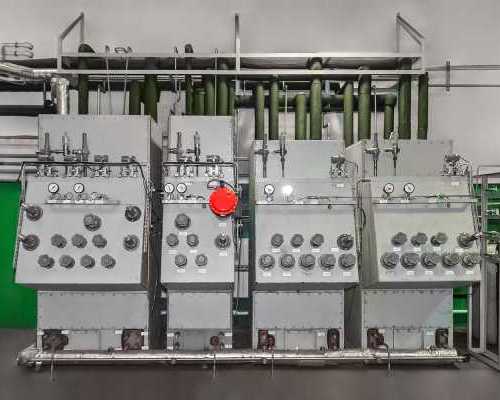

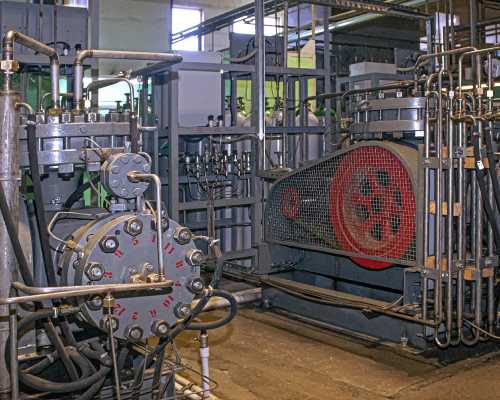

The processing unit is designed for the production of high-purity helium from the stripping stream obtained during the production of neon.

The composition of the stripping stream:

The stripping stream enters from the neon production after passing through the purification unit, so the composition of the remaining impurities corresponds to the product with a 6.0 grade (99.9999%).

The processing unit is designed for the production of high-purity helium from the stripping stream obtained during the production of neon.

The composition of the stripping stream:

CJSC “ColdGasEngineering”

127410, Russia, Moscow,

Altufevskoe highway, 79A, building 3

E-mail: Info@CGE-gas.ru