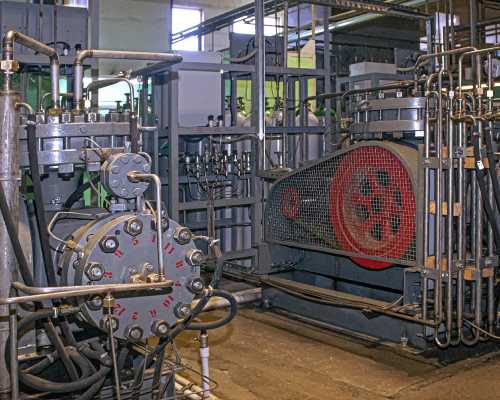

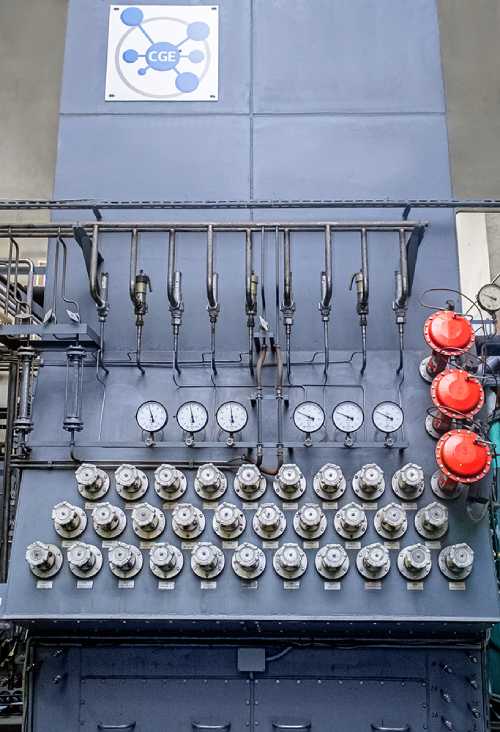

Krypton and Xenon production at CJSC ColdGasEngineering is based on the URKrK-25 refinery processing unit designed and manufactured by the company.

The main mode of the processing unit is designed for the simultaneous production of high-purity krypton and xenon from a krypton-xenon mixture (GOST 10218-77) obtained at air separation plants of metallurgical industries.

The mixture enters in steel or aluminum cylinders under pressure.

GOST 10218-77 establishes the following requirements for the mixture in terms of the content of components:

All xenon and krypton produced by us correspond to 6.0 grade (99.9999%) in purity.

By special order, we produce products of 7.0 grade (99.99999%), for individual impurity components reaching ppb units.

Krypton and xenon are pumped by membrane compressors into steel or aluminum cylinders with a capacity of 1 L to 50 L.

Maximum injection pressure up to 200 kgf/cm2.

All xenon and krypton produced by us correspond to 6.0 grade (99.9999%) in purity.

By special order, we produce products of 7.0 grade (99.99999%), for individual impurity components reaching ppb units.

Krypton and xenon are pumped by membrane compressors into steel or aluminum cylinders with a capacity of 1 L to 50 L.

Maximum injection pressure up to 200 kgf/cm2.

Productivity of the processing unit (in the main mode) is up to 25 m3 processed mixture per hour *

* flow rate is based on “normal” conditions: pressure 101.325 kPa (760 mmHg) and temperature 293.16 K (20 °C).

The technological scheme of the processing unit allows you to have an arbitrarily large resource of work.

Real annual plant capacity: krypton – 100 000 m3/year; xenon – 10 000 m3/year.

Krypton and Xenon production at CJSC ColdGasEngineering is based on the URKrK-25 refinery processing unit designed and manufactured by the company.

The main mode of the processing unit is designed for the simultaneous production of high-purity krypton and xenon from a krypton-xenon mixture (GOST 10218-77) obtained at air separation plants of metallurgical industries.

The mixture enters in steel or aluminum cylinders under pressure.

GOST 10218-77 establishes the following requirements for the mixture in terms of the content of components:

All xenon and krypton produced by us correspond to 6.0 grade (99.9999%) in purity.

By special order, we produce products of 7.0 grade (99.99999%), for individual impurity components reaching ppb units.

Krypton and xenon are pumped by membrane compressors into steel or aluminum cylinders with a capacity of 1 L to 50 L.

Maximum injection pressure up to 200 kgf/cm2.

Productivity of the processing unit (in the main mode) is up to 25 m3 processed mixture per hour *

* flow rate is based on “normal” conditions: pressure 101.325 kPa (760 mmHg) and temperature 293.16 K (20 °C).

The technological scheme of the processing unit allows you to have an arbitrarily large resource of work.

Real annual plant capacity: krypton – 100 000 m3/year; xenon – 10 000 m3/year.

CJSC “ColdGasEngineering”

127410, Russia, Moscow,

Altufevskoe highway, 79A, building 3

E-mail: Info@CGE-gas.ru